TESTIMONIALS

TESTIMONIALS

I have been a practicing potter for over 60 years, starting with my first studies in 1947. I used several small kilns but as my skills progressed became interested in a serious kiln. This was before the Internet, but I researched kilns through Ceramics Monthly and decided to buy an early square L&L kiln. My decision was mainly based on the element holders where the unprotected grooves often broke in my earlier kilns.

Website: Bonnie Staffel Gallery Instagram: @bonniestaffel

I make a living out of my five L&L kilns. I really beat them up firing them at least three times a week to cone ten. They take a real beating and keep on going.

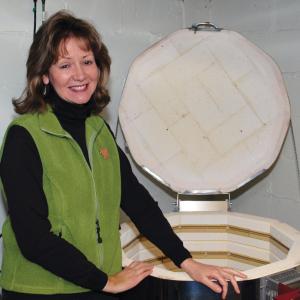

Diane chooses to fire in an L&L JD230 for number of reasons. The fully opening lid allows her to load her larger sculptures in without the impediment of a lid prop and the durable ceramic holders have kept the kiln in like-new condition. She switched to L&L because of the deterioration of the element channels in her last kiln. She is commonly loading larger tiles and needs the extra durability on the faces of the firebrick.

Conestoga has always used L&L kilns – going back over 30 years. Why? They hold up to the heavy use of this ambitious program.

At this moment the smallest of my kilns, the JD-18, the one that we put in the quad element sides, is in the middle of firing number 121 on that set of elements. Wow!

Website: tiltonpottery.com Instagram: @tiltonpottery

These kilns keep looking new for decades because of the element holders. Now with the zone control, they fire absolutely evenly from top to bottom. All of this excellent engineering, along with their reasonable prices, make L&L the best electric kiln on the market.

Website: lisaorr.com/

My very first solo firing was in an L&L kiln and since then I've formed a special bond with the brand, coincidentally encountering them in multiple shared studio spaces where I've worked independently. The relationship between potter and kiln feels like a lifelong one, and I'm very happy to have found my match!

Website: https://www.youtube.com/@rajivsurendra Instagram: https://www.instagram.com/rajivsurendra/

Richarch Wukich went to Iraq as part of a program to make ceramic water filters. He got L&L to build him a special Dura-Fire kiln to fire these pots.

Roberta Griffith used L&L Kilns for her ceramic classes at Hartwick College for more than 35 years. She is now working in Hawaii.

Saramics’ Sara Meadows of Kennet Square, Pennsylvania poses with her new L&L e23t-3 kiln. The e23t-3 is the perfect balance of size and power. It is rated for cone 10 across all voltage and phase configurations. This top selling model of all L&L kilns delivers the power needed for your high temperature firings. At 23″ interior diameter x 27″ interior height, it is the perfect size for most home studios! Sara makes the most lovable ceramic sculptures.

Website: creationsgallery.com/sara-meadows

The kiln is obviously an integral part of my process, I make the work and my kiln finishes it. My glazes articulate the forms. It is imperative that the kiln in which they are fired is reliable, making it an indispensable tool for me. My time is valuable and, for this reason, the kiln needs to be low maintenance and consistent.

I have had several kilns (three other popular brands) and L&L. The L&L is my favorite and I find that the construction of the kiln with the ceramic element holders, better withstands the test of time and use.

After 45 years of gas reduction firing, Tom Turner has gone electric with his electrogama.

Creating, loading and unloading a 65 pound pot is not pretty, but my L&L is tough enough to make it possible. This is my favorite kiln. I know I can count on it every time.

Willi Singleton was trained in Japan. He digs his own clay. He wood fires in his own anagama kiln. He bisques in an L&L.